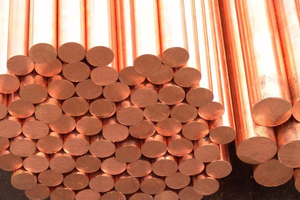

supplies C18200 Chromium Copper in round bar and rod. Our particular specification is the military grade (MIL-C-19311) and is mainly used for parts in the electrical and industrial markets. It is excellent in being cold formed and good in being hot formed. Our dedicated sales staff can provide you information about our sizes and is ready to help meet your exact needs

Chromium copper alloys are high copper alloys, containing 0.6 to 1.2% Cr. The chromium copper alloys are used for their high strength, corrosion resistance and electrical conductivity. The chromium copper alloys are age hardenable, which, in this case, means that a change in properties occurs at elevated temperature due to the precipitation of chromium out of the solid solution. The strength of fully aged chromium copper is nearly twice that of pure copper and its conductivity remains high at 85% IACS, or 85% that of pure copper. These high strength alloys retain their strength at elevated temperatures.

The corrosion resistance of chromium copper alloys is better than that of pure copper because chromium improves the chemical properties of the protective oxide film. Chromium copper has excellent cold formability and good hot workability. It is used in applications such as resistance welding electrodes, seam welding wheels, switch gears, cable connectors, circuit breaker parts, molds, spot welding tips, and electrical and thermal conductors that require strength. Chromium copper alloys are designated as UNS C18050 through C18600, the cast alloys are C81400 through C81540.

| Standards | CC102 / CW106C |

| Hardness | Soft, Half Hard, Quarter Hard |

| Alloy | Yes |

| Shape | Square, Rectangular, Round |

| Surface Treatment | Tinned, Silver Finish, Bright |