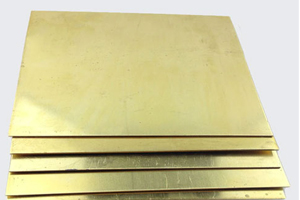

Description

Brass Sheets Plates Coils, which are all prone to sigma phase formation if exposed for long periods to a temperature of about 590 Degree C to 870 Degree C. The problem of grain boundary carbide precipitation in Brass Plates was discussed under inter – granular corrosion. This same phenomenon occurs when Brass Coils are exposed in service to temperatures of 425 Degree C to 815 Degree C, resulting in a reduction of corrosion resistance which may be significant. If this problem is to be avoided the use of stabilised grades such as Brass Slatting Coils should be considered.

A further problem that Brass Perforated Coils have in high temperature applications is the formation of sigma phase. The formation of sigma phase in Brass Plates is dependent on both time and temperature and is different for each type of steel. In general, Brass Coils is practically immune to sigma phase formation, but not so those grades with higher chromium contents with molybdenum or with higher silicon contents. Sigma phase embrittlement refers to the formation of a precipitate in the microstructure of Brass Slatting Coils over a long period of time within this particular temperature range. Generally, beta – phase Brass Perforated Coils is the more ductile phase and alpha – phase is stronger yet less ductile, due to the larger number of slip planes in the bcc structure of the beta – phase in comparison to the hcp alpha – phase.

Brass UNS C36000 Plates, Brass Coils, Brass Plates, Brass Hot Rolled Sheets, ASME SB 62 Plate, Carpenter Plate, Brass Circle, Brass Hot Rolled Plates Supplier in Mumbai, India.